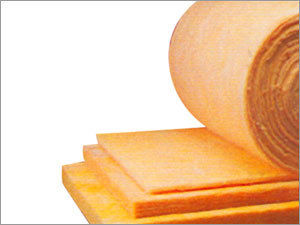

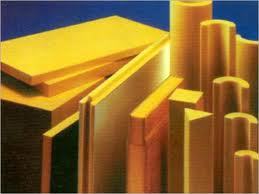

Resin Bonded Fibre Glass Wool

Resin Bonded Fibre Glass Wool Specification

- Coating Type

- Aluminium foil (optional)

- Feature

- Lightweight, Fire resistant, Water repellent, Non-corrosive, Eco-friendly

- Thermal Conductivity

- 0.032 0.040 W/mK

- Layer

- Single or Multi-layer (as required)

- Size

- Rolls or Slabsstandard sizes available

- Installation Guideline

- Easy to cut and install, use protective gear during handling

- Surface Treatment

- Plain, Aluminium foil faced (as per requirement)

- Density

- 48 Gram per cubic centimeter(g/cm3)

- Product Type

- Thermal and Acoustic Insulation

- Material

- Resin Bonded Fibre Glass Wool

- Tensile Strength

- High tensile strength

- Width

- 600 mm

- Thickness

- 25 mm, 50 mm (customizable)

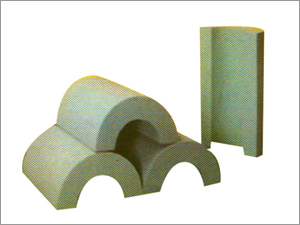

- Application

- Thermal insulation, Acoustic insulation, HVAC, Ducts, Roofs, Walls, Industrial insulation

- Heat Conductivity

- 0.032 0.040 W/mK

- Color

- Yellow

- Max Withstanding Temperature

- up to 250C

- Chemical Resistance

- Resistant to most chemicals

- Sound Absorption Coefficient

- Up to 1.00 NRC

- Fungi & Bacteria Resistance

- Unaffected by fungi and bacteria

- Water Vapour Absorption

- Minimal

- Moisture Absorption

- < 1% by volume

- Odour

- Odourless

- Compressive Strength

- Sufficient to resist deformation during installation

- Service Life

- Longover 20 years with proper installation

- Fire Resistance

- Class 1

About Resin Bonded Fibre Glass Wool

Resin Bonded Fibre Glasswool

KIMMCO (Kuwait Insulating Material Manufacturing Company) an affiliate of Alghanim Industries Is the Middle East market Leader in thermal & Accoustical Insulation Product. With a Glasswool Plant in Kuwait.

KIMMCO fibers begin with sand, soda and other components, which are melted to from glass and Then processed to form thin, resilient fibers.

The Glass wool is formed into products with various thickness and densities.

KIMMCO (Kuwait Insulating Material Manufacturing Company) an affiliate of Alghanim Industries Is the Middle East market Leader in thermal & Accoustical Insulation Product. With a Glasswool Plant in Kuwait.

KIMMCO fibers begin with sand, soda and other components, which are melted to from glass and Then processed to form thin, resilient fibers.

The Glass wool is formed into products with various thickness and densities.

| Density | Max. Service Temp | Dimensions | Facing |

|

16,24,32,& 48 |

25,40,50,75 & 100 |

1.2 M x 20 M |

Unfaced, Al.Foil, Vinyl,Metalized Polyester, Kraft Paper, Glass Tissue |

Superior Fire and Moisture Resistance

Resin Bonded Fibre Glass Wool stands out due to its Class 1 fire resistance rating, making it a safe choice for building and industrial applications. Its moisture absorption is below 1% by volume, helping maintain integrity and performance even in humid environments. The products odourless nature further ensures a pleasant working and living space.

Exceptional Acoustic and Health Properties

This insulation material boasts an excellent sound absorption coefficientup to 1.00 NRCmaking it ideal for noise-sensitive areas. Additionally, it is unaffected by fungi and bacteria, providing a hygienic solution for spaces that prioritize health and air quality. The chemical resistance and minimal water vapour absorption contribute to its durability.

Long-Lasting Performance and Versatile Use

Resin Bonded Fibre Glass Wool offers a robust service life of more than 20 years when correctly installed. Its compressive strength prevents deformation, making installation straightforward and reliable. Widely available across India, the product supports efficient insulation for buildings, offices, factories, and commercial establishments.

FAQs of Resin Bonded Fibre Glass Wool:

Q: How does the Resin Bonded Fibre Glass Wool provide fire resistance?

A: This product achieves a Class 1 fire resistance rating through a special bonding process, using resin that helps withstand high temperatures and prevent fire spread, making it suitable for safety-critical applications.Q: What benefits does its minimal moisture absorption bring to users?

A: With less than 1% moisture absorption by volume, the wool resists humidity-induced deterioration, ensuring stable thermal and acoustic performance and reducing the risk of mould or structural damage over time.Q: When should Resin Bonded Fibre Glass Wool be installed for optimal results?

A: For maximum effectiveness, the wool should be installed during new construction or refurbishment, ensuring proper placement to achieve its full insulating and sound absorption benefits throughout its lengthy service life.Q: Where can this insulation material be used?

A: It can be employed in commercial, residential, industrial, and institutional buildings, including offices, factories, hospitals, schools, and public spaces, especially where fire safety and acoustic control are priorities.Q: What is the recommended process for installing Resin Bonded Fibre Glass Wool?

A: Installation involves placing the wool sheets or rolls between walls, ceilings, or floors, ensuring they are not compressed beyond their design; this maintains their insulation properties and prevents deformation due to their robust compressive strength.Q: How does the product remain unaffected by fungi and bacteria?

A: The materials composition resists microbial growth, making it ideal for maintaining hygienic conditions in environments that demand high standards of cleanliness, such as hospitals and food processing areas.Q: What are the long-term benefits of choosing Resin Bonded Fibre Glass Wool for insulation?

A: Clients enjoy reliable fire and acoustic protection, chemical and microbial resistance, minimal upkeep needs, and a service life exceeding 20 years, which together offer substantial savings and improved environmental quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Insulation Foam and material Category

Phenotherm Phenolic Foam

Color : Brown

Product Type : Thermal Insulation Board

Material : Phenolic Foam

Application : Insulation and ducting in HVAC, industrial and building construction

Thermal Conductivity : 0.02 W/mK

Insulation materials

Minimum Order Quantity : 10 Pieces

Color : Yellow

Product Type : Insulation materials

Material : Insulation

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese