Phenotherm Phenolic Foam

Phenotherm Phenolic Foam Specification

- Feature

- Fire Retardant, Low Smoke Emission, Moisture Resistant

- Size

- 600 mm x 1200 mm

- Installation Guideline

- Use recommended adhesive or mechanical fixings

- Thermal Conductivity

- 0.02 W/mK

- Surface Treatment

- Paper Clad or Plain

- Product Type

- Thermal Insulation Board

- Material

- Phenolic Foam

- Rated Voltage

- 220 V

- Width

- 600 mm

- Thickness

- 25 mm to 100 mm

- Application

- Insulation and ducting in HVAC, industrial and building construction

- Breakdown Voltage

- 20 kV/mm

- Color

- Brown

- Max Withstanding Temperature

- Up to 150C

About Phenotherm Phenolic Foam

Persistently marching in todays competitive market, our company is recognized as one of the well established manufacturers and suppliers of Phenotherm. The offered range of phenotherm is checked by our quality analyzers on various parameters so as to ensure the quality of the product. This phenotherm find wide usage in various application of construction industry such as under-dec and over-deck (roof) insulation, suspended ceilings and residential buildings & hospitals. Our offered range of Phenotherm is best known in the market due to its features such as high durability and effective performance.

Further Details:

Phenothem is the ultimate insualtion system for the construction and Building Services Industry, phenolic foam is a versatile material with a wide field of utility.Application Areas

Pipe and duct insulation, Insualtion fo vessels, Pipelines in Petrochemical, Fertilizer Chemical and Pharmaceutical Plants and Refineries. Insulation of Cold Storage and Refrigerated Rooms, High Altitude Huts, Refrigerated Rails, Surface and Marine Containers.

| Product |

Density Kg/m2 |

Thk (mm) |

Size |

Facing |

Slab |

35, 40, 50, 60 |

30, 55 40, 50, 60 75 |

1M x 1M; 1M x 1/2M; 2 x 2; 4 x 2 1M X 1M; 1 M x 1/2 M 1M x 1/2 M |

Kraft Paper, Aluminium, Decorative Laminates, Decorative Paper |

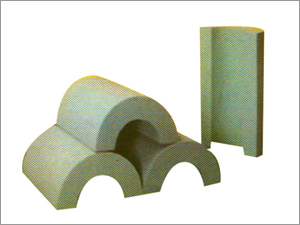

| Pipe Section |

40 to 50 |

25, 55, 40, 50, 60, 75 & 100 |

1/2" to 14" NB |

Aluminium |

Premium Insulation for Critical Applications

Phenotherm Phenolic Foam provides exemplary insulation for HVAC ducting, industrial setups, and building construction. The foams ability to withstand temperatures up to 150C and deliver minimal thermal conductivity ensures reliable performance even in demanding environments. As a product available through various channels in India, it meets both regulatory and functional standards.

Key Features for Enhanced Safety and Efficiency

Safety is paramount with Phenotherm Phenolic Foam. The materials fire retardant characteristics, along with its low smoke emission and strong moisture resistance, make it a preferred choice in sensitive installations. The product is available in paper clad or plain finish, catering to various project requirements and installation settings.

FAQs of Phenotherm Phenolic Foam:

Q: How should Phenotherm Phenolic Foam be installed for optimal insulation?

A: Phenotherm Phenolic Foam should be installed using recommended adhesive products or mechanical fixings to ensure a secure and effective fit. Proper installation in line with manufacturer guidelines maximizes insulation benefits and safety.Q: What applications are best suited for this phenolic foam?

A: This foam is ideal for insulation and ducting in HVAC systems, as well as use in industrial and building construction projects due to its robust fire retardancy and moisture resistance.Q: When is it necessary to choose the paper clad variant over the plain type?

A: The paper clad surface treatment is recommended for installations where additional surface protection or improved compatibility with adhesives is required, while plain variants are suitable for direct fitment in controlled environments.Q: Where can Phenotherm Phenolic Foam be sourced or procured in India?

A: It is readily available across India through distributors, exporters, importers, manufacturers, service providers, suppliers, and traders dealing in insulation materials.Q: What is the manufacturing process behind this phenolic foam?

A: The foam is manufactured using advanced polymerization and curing processes to create rigid boards with consistent thickness and physical properties, ensuring high breakdown voltage and temperature resilience.Q: How does Phenotherm Phenolic Foam benefit energy efficiency and safety?

A: Its low thermal conductivity (0.02 W/mK) enhances energy efficiency, while fire retardant properties and low smoke emission significantly improve safety during fire incidents.Q: What maintenance does the installed phenolic foam require over time?

A: Once installed properly, Phenotherm Phenolic Foam requires minimal maintenance, primarily periodic inspection to ensure integrity and renewal of surface protection if necessary.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Insulation Foam and material Category

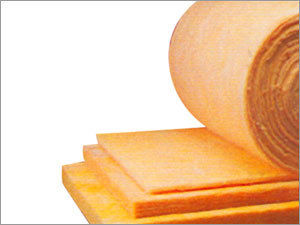

Resin Bonded Fibre Glass Wool

Application : Thermal insulation, Acoustic insulation, HVAC, Ducts, Roofs, Walls, Industrial insulation

Product Type : Thermal and Acoustic Insulation

Material : Resin Bonded Fibre Glass Wool

Color : Yellow

Width : 600 mm

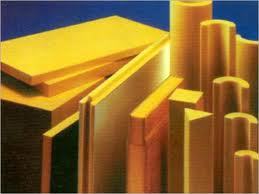

Insulation materials

Minimum Order Quantity : 10 Pieces

Application : Industrial

Product Type : Insulation materials

Material : Insulation

Color : Yellow

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese