Rockwool Pipe Sections

Rockwool Pipe Sections Specification

- Size

- Suitable for pipe diameters to 14 (and custom sizes available)

- Feature

- Fire resistant, acoustic, and thermal insulation

- Thermal Conductivity

- 0.035 0.040 W/mK

- Installation Guideline

- Sections are split and hinged for easy installation around pipelines

- Product Type

- Preformed Pipe Section

- Material

- Rockwool (Mineral Wool)

- Width

- Varies as per diameter (typically 1 meter length)

- Thickness

- 25 mm to 100 mm

- Application

- Thermal insulation of hot and cold pipelines in industrial and commercial installations

- Heat Conductivity

- 0.035 0.040 W/mK (at 20C)

- Max Withstanding Temperature

- Up to 750C

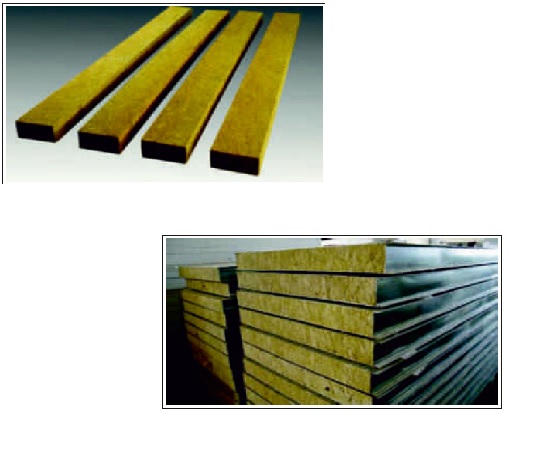

About Rockwool Pipe Sections

Rockwool Pipe Sections

With the help of our manufacturing unit& experienced personnel, our company brings forth an exclusive range of Rigid Pipe Sections. We have manufactured this pipe using topmost quality materials in compliance with international quality standards. In addition to this, these pipe sections are stringently checked on certain parameters and norms. We are offering the pipe sections to our valued clients at cost effective prices. The Rigid Pipe Sections are highly appreciated in the domestic and international market due to high performance, compressive strength and durability.

Specifications:

| Density | Max. Service Temp | Dimensions | Application | Facing |

| 144 Kg/m3 | 750.C | 1.25 M (L) (Thk-mm) 25, 40, 50, 65, 75, 100 | Steam & Process Piping, Air Conditioning System, Round Ducts up to 14" | Unfaced, Alu. Foil, |

Standards: IS 9842, BS - 3958 Part 4 & ASTM - C - 547.

Exceptional Thermal and Fire Insulation

Rockwool Pipe Sections deliver reliable heat management and fire resistance, making them the preferred choice for insulating hot and cold pipelines across a variety of industries. Their mineral wool composition ensures minimal heat loss, and they are capable of withstanding high temperatures up to 750C, offering peace of mind in demanding environments.

Versatile Sizing and Easy Installation

Available for pipe diameters from up to 14, with options for custom dimensions, these pipe sections suit a broad range of applications. Their split and hinged construction allows for fast, straightforward installation around existing pipelines, minimizing labor costs and downtime during process upgrades or routine insulation enhancements.

FAQs of Rockwool Pipe Sections:

Q: How do Rockwool Pipe Sections enhance the thermal performance of pipelines?

A: Rockwool Pipe Sections significantly reduce heat loss due to their low thermal conductivity (0.0350.040 W/mK), helping to maintain stable temperatures in both hot and cold pipelines. This results in improved energy efficiency and system cost savings.Q: What are the key advantages of using mineral wool insulation for pipelines?

A: Mineral wool insulation provides outstanding thermal, fire, and acoustic resistance. It is non-combustible, offers effective noise reduction, and remains stable at high temperatures, making it ideal for demanding industrial settings.Q: When should Rockwool Pipe Sections be installed on pipelines?

A: Rockwool Pipe Sections can be installed during initial pipeline construction, renovations, or retrofitting processes. They are especially recommended whenever thermal insulation, fire safety, or noise reduction is required in pipeline systems.Q: Where can these insulation pipe sections be applied?

A: These pipe sections are suitable for both industrial and commercial installations, including process plants, HVAC systems, refineries, and any facility that requires thermal insulation for its pipework.Q: What is the process for installing Rockwool Pipe Sections?

A: Installation is straightforward due to the split and hinged design. Simply position the section around the pipeline, close it securely, and fix it as directed. This design enables quick fitting, even in difficult-to-access areas.Q: How do Rockwool Pipe Sections contribute to safety?

A: Rockwool is inherently fire-resistant and capable of withstanding temperatures up to 750C, offering critical protection against fire hazards in pipelines. Its acoustic insulation also helps reduce noise levels within facilities, further improving safety and working conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Insulation Material Category

Thermal Insulation

Minimum Order Quantity : 50 Kilograms

Product Type : Thermal Insulation

Application : Industrial

Acoustic Insulation

Minimum Order Quantity : 50 Kilograms

Product Type : Acoustic Insulation

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese